- H2-Heat Quarterly Newsletter

- Posts

- H2Heat June Newsletter

H2Heat June Newsletter

Welcome to the June 2025 edition of the H2Heat Project Newsletter! As we continue our mission to demonstrate the complete value chain of green hydrogen for heating commercial buildings, we are excited to share the latest developments in the hydrogen industry. These advancements highlight the growing momentum in the sector and provide valuable insights that can inform and inspire our work within the H2Heat project.

Pioneering Green Hydrogen for Hospital Decarbonisation

The H2HEAT project is set to demonstrate the entire value chain for green hydrogen (H2) production and its practical application in building heating, with a special focus on hospital facilities. Through a landmark collaboration between the Canary Island Health Service (SCS) and project coordinator PLOCAN, H2HEAT will drive the generation of renewable energy, the production of green H2, and its use to decarbonise SCS hospitals across the Canary Islands. This initiative directly supports the SCS’s ambitious ‘Health Zer0 net Emissions Strategy 2030’, aiming for deep decarbonisation in the health sector.

Cutting-Edge Innovations in Hydrogen Technology

At the heart of H2HEAT’s innovation is Stargate’s 1MW electrolyser, which will produce green hydrogen to replace conventional fuels at a major SCS hospital. Stargate’s development of advanced ceramics-based electrode materials promises high efficiency and lower costs, setting new standards in electrolyser technology. The green hydrogen produced will power a state-of-the-art 100% hydrogen-fuelled cogeneration system (H2-CHP) from partner 2G, delivering heating to the University Maternal and Children’s Island Hospital (CHUIMI). This system will be further enhanced by integrating a heat pump, significantly boosting the hospital’s heat supply and demonstrating a novel, efficient approach to hospital energy management.

Renewable Energy and Digital Integration

H2HEAT will harness offshore renewable energy, to ensure a sustainable supply of electricity for hydrogen production. The project will also introduce advanced digital solutions, including a comprehensive control system for H2 production and sophisticated energy and demand management systems (EMS/DMS), as well as SCADA for real-time monitoring and optimisation.

Maximising Value and Replicability

The project will establish a complete end-to-end infrastructure for H2 production, transport, and use, all managed from a centralised facility. H2HEAT is designed as a replicable model, paving the way for widespread adoption across SCS hospitals and making a significant contribution to reducing the 40% of energy consumption and 36% of greenhouse gas emissions attributed to buildings in the EU.

Connecting Hydrogen Europe 2025

Connecting Hydrogen Europe 2025 (CHE2025) took place in Madrid on June 18-19, 2025. The event attracted over 6,000 participants, including industry leaders, policymakers, innovators, and experts from across Europe and beyond. With more than 200 speakers and 100 exhibitors, CHE2025 offered a comprehensive platform to showcase cutting-edge hydrogen technologies and fostered collaboration across the entire hydrogen value chain.

Ana Marcos de los Rios, Project Manager of H2Heat with Diego Schaefer Dalmau, Hydrogen Project Engineer

Highlights include a C-Level Strategic Summit featuring visionary discussions on hydrogen infrastructure, supply chains, and market development. The event also hosted the H2Innovate Next Summit and an extensive exhibition space covering electrolysis, hydrogen storage, fuel cells, renewable energy, and sustainable fuels.

Attendees engaged in diverse networking opportunities such as one-on-one meetings, master classes, and delegate lounges, making it an unparalleled forum for building partnerships and driving Europe’s hydrogen economy forward.

A special highlight was meeting Eiji Ohira, Strategy Architect at Kawasaki Heavy Industries, who shared Kawasaki’s vision and long-standing expertise in liquefied hydrogen transport. Drawing from their decades of experience in LNG and cryogenic systems, he emphasized the potential of LH2, despite its energy demands, and how cold energy recovery could help increase system efficiency at the delivery point.

CHE2025 is recognized as Europe’s leading and most influential hydrogen conference, providing critical insights into accelerating hydrogen deployment and shaping the continent’s clean energy future.

José Ignacio Hormaeche Azumendi, Director General, highlights the Basque Country’s pivotal role in catalyzing regional transformation through hydrogen.

The Basque Country has been driving 7 industrial value chains for over 30 years, with a growing focus in the last decade on the energy transition. Within this framework, Value Chain 12: Hydrogen and Recycling, led by the Petronor refinery (part of the Repsol group), represents a strategic opportunity for local companies seeking to diversify into sustainable technologies.

The Basque Energy Cluster plays a crucial role in this chain by supporting hydrogen technology development through R&D activities, systems integration, and pilot solutions. Additionally, it promotes internationalization, fosters specialized talent, and helps companies meet ESG goals and energy efficiency standards.

Hydrogen News June 2025

We are bringing you the latest updates from the hydrogen energy world in June 2025:

U.S. Hydrogen Tax Credit Faces Accelerated Expiry, Raising Industry Concerns

The U.S. clean hydrogen production tax credit under Section 45V, originally set to expire in 2033, is now facing an accelerated termination date of January 1, 2026, as proposed in the recent tax legislation advanced by the Senate Finance Committee and passed by the House under former President Trump’s administration. This move significantly shortens the timeframe for hydrogen projects to qualify for the credit, requiring construction to begin by the end of 2025 instead of 2033.

Industry stakeholders warn that this accelerated deadline could derail many planned green and blue hydrogen projects, as the tight timeline leaves insufficient room for investment decisions and project development. The tax credit, which offers up to $3 per kilogram of clean hydrogen depending on carbon intensity, was designed to catalyse the growth of the U.S. hydrogen sector and help lower production costs to competitive levels.

Clean energy advocates and hydrogen producers have urged lawmakers to extend the credit’s eligibility period to 2029, aligning it with other renewable incentives, but the current legislative proposal maintains the earlier termination date.

Experts caution that removing or shortening the credit risks undermining U.S. competitiveness in the global hydrogen market, potentially ceding ground to regions like Europe and China where governments continue to support hydrogen development aggressively. The accelerated expiry of the 45V credit represents a significant policy shift that could slow the momentum of clean hydrogen investment and impact job creation in the emerging hydrogen economy.

India’s First Off-Grid 5 MW Green Hydrogen Plant Goes Live in Gujarat

Adani New Industries Limited (ANIL) has successfully commissioned India’s first off-grid 5 MW green hydrogen pilot plant in Kutch, Gujarat. This pioneering facility operates entirely independently of the traditional power grid, powered 100% by solar energy and integrated with a Battery Energy Storage System (BESS), marking a breakthrough in decentralized renewable hydrogen production. The plant features a fully automated, closed-loop electrolyser system that dynamically adjusts to real-time solar energy inputs, ensuring operational flexibility, safety, and high efficiency despite the variability of renewable power.

The innovation sets a new benchmark for off-grid green hydrogen production in India and supports the country’s National Green Hydrogen Mission. This pilot project also serves as a proof of concept for ANIL’s upcoming large-scale Green Hydrogen Hub in Mundra, which aims to significantly contribute to India’s low-carbon transition by producing green hydrogen and its derivatives for hard-to-abate sectors such as fertilizers, refining, and heavy transport. The initiative reinforces India’s ambition to become a global hub for green hydrogen production and sustainable industrial applications.

Hydrogen Buses Hit the High Mountains of Ladakh

In a groundbreaking step for sustainable transport, Ladakh has introduced its first five hydrogen fuel-cell buses in the Leh district, marking India’s debut in high-altitude zero-emission public mobility. These buses are specially designed to operate efficiently in the challenging mountainous terrain and extreme weather conditions of the region, setting a global benchmark for green mobility in high-altitude areas.

The hydrogen buses not only reduce air pollution in this ecologically sensitive zone but also demonstrate the viability of clean hydrogen technology for public transportation in remote and harsh environments. This initiative aligns with India’s broader goals to promote renewable energy and reduce carbon emissions, showcasing how hydrogen fuel-cell vehicles can play a pivotal role in transforming mobility across diverse geographies.

Tasmania’s $2 bn green methanol hub

Tasmania is set to strengthen its hydrogen credentials with the Bell Bay Powerfuels project, a $2 billion initiative led by ABEL Energy and Iberdrola Australia. Scheduled to start operations by 2028, the project will deploy a 240 MW electrolyser to produce renewable hydrogen, which will then be combined with biomass-derived carbon to generate approximately 300,000 tonnes of green methanol annually.

This large-scale facility, located in Northern Tasmania’s Bell Bay Advanced Manufacturing Zone, aims to decarbonise sectors such as shipping by supplying green methanol as a low-carbon transport fuel. The project will leverage Tasmania’s abundant renewable energy resources, including hydro and new wind power capacity, to power electrolysis and biomass gasification processes.

Supported by $70 million in federal government funding under the Regional Hydrogen Hubs program, Bell Bay Powerfuels also benefits from strong local partnerships and infrastructure, including a deep-water port for methanol export. Front-end engineering design (FEED) is underway, with major technology suppliers selected for methanol synthesis and electrolysers.

The Bell Bay project is an example of Tasmania’s ambition to become a prominent country in green hydrogen and fuels, creating hundreds of jobs and supporting the state’s transition to a low-carbon economy.

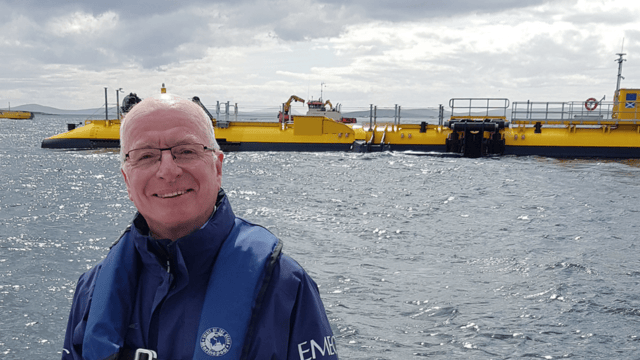

COULD SYNTHETIC AVIATION FUELS OFFER A SMARTER PATH FOR SCOTLAND’S ENERGY TRANSITION?

Neil Kermode, Managing Director of the European Marine Energy Centre (EMEC) in Orkney, highlights a promising path for Scotland’s energy transition: combining green hydrogen with captured CO2 to produce synthetic aviation fuel. Unlike hydrogen alone, this fuel is energy-dense, easier to transport, and compatible with existing engines and refuelling infrastructure, offering a practical solution for decarbonising aviation.

This is not just theory. In 2021, EMEC supported Zero Petroleum in producing synthetic gasoline from green hydrogen at its Billia Croo wave energy test site. The fuel powered a Royal Air Force flight that set a Guinness World Record as the first aircraft powered by synthetic fuel, performing identically to fossil gasoline.

Scotland’s abundant renewable resources, especially in Orkney, and expertise in hydrogen and carbon capture position it well to scale up synthetic fuel production. With grid limitations restricting electricity export, turning green hydrogen and CO2 into synthetic fuels could leverage existing infrastructure and create a valuable, sustainable aviation fuel, an idea that plays to Scotland’s strengths and merits strong pursuit.